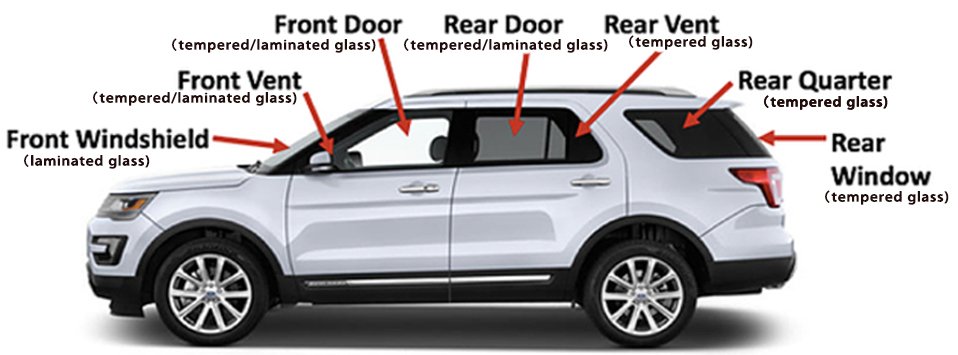

Automotive glass application scenarios and main types

Front windshield (laminated glass) / Front vent (tempered /laminated glass) skylight (tempered/laminated glass) / Front door (tempered/laminated glass)

Rear door (tempered glass/laminated glass) / Rear vent (tempered glass) Rear quarter (tempered glass) / Rear window (tempered glass)

Tempered glass:

The glass is heated to near the softening temperature, and the glass is quickly uniformly quenched with low temperature and high speed air flow, so that the inner layer of the glass produces tensile stress and the outer surface produces compressive stress. The glass treated in this way is called tempered glass. Tempered glass features: 1, high impact strength: is the same thickness of ordinary glass 5-8 times; 2, bending strength: 3-5 times of ordinary glass; 3, with good thermal stability; 4, good safety performance, when the tempered glass is broken, the fragments into honeycomb obtuse particles, not easy to hurt.

Laminated glass:

Is composed of two or more pieces of glass, sandwiched between a layer or multiple layers of organic polymer intermediate film, after special high temperature prepressing (or vacuum) and high temperature and high pressure process, make the glass and the intermediate film permanently bonded as one of the composite glass products.

Commonly used laminated glass interfilm are: PVB, SGP, EVA, PU and so on.

In addition, there are some special ones such as colored interfilm laminated glass, SGX printed interfilm laminated glass, XIR LOW-E interfilm laminated glass and so on. Embedded decorative pieces (metal mesh, metal plate, etc.) laminated glass, embedded PET material laminated glass and other decorative and functional laminated glass.